RF and microwave test labs are dynamic environments with connectors everywhere. They’re found on cable assemblies, precision adapters, and attenuators, requiring the right torque wrenches to secure connections. With many connectors looking nearly identical, it’s easy to mate incompatible pairs – a simple misstep that can compromise measurement accuracy, equipment integrity, and the ability to meet project deadlines.

This blog explores the importance of choosing the right connector for your needs, and how color-coded visual markers ensure the correct choice is made every time.

Connector Compatibility

With pressing time constraints and frequent setup changes, engineers swap connectors in and out regularly. A few typical ways connectors are paired in a test environment include:

- Connecting matching connector types, such as SMA to SMA or 2.92 mm to 2.92 mm.

- Mating compatible types that share mechanical characteristics, such as high-quality SMA, 3.5mm, and 2.92mm. Similarly, 2.4 mm and 1.85mm are mechanically compatible with each other.

- Using adapters to connect incompatible pairs, joining connectors safely from different, mechanically diverse groups.

The subtle differences between connectors can easily be overlooked when grabbed off a test bench in busy labs. Accidentally mating incompatible pairs can cause serious issues, such as:

- Damage to delicate sockets or center pins

- Stripped or damaged threads

- Test port damage to expensive equipment

- Costly repairs that threaten tight timelines

- Faulty or non-existent connections that affect signal integrity and measurement accuracy

Connectors require the right torque wrench to secure electrical contact for reliable and consistent performance. Under-torquing results in loose connections and higher insertion loss, while over-torquing damages threads and deforms internal contacts.

Choosing the appropriate torque wrench isn’t always straightforward. For example, different connector types like SMA require 5 in-lb and 3.5 mm and 2.92 mm require 8 in-lb torque, even though they both share the same 5/16” hex interface.

Improve Your Test Setup with Color-coded Connectors

Color-coded markers simplify connector identification. With standardized, visual cues, engineers can instantly recognize compatibility, select the right torque wrench, and streamline workflows.

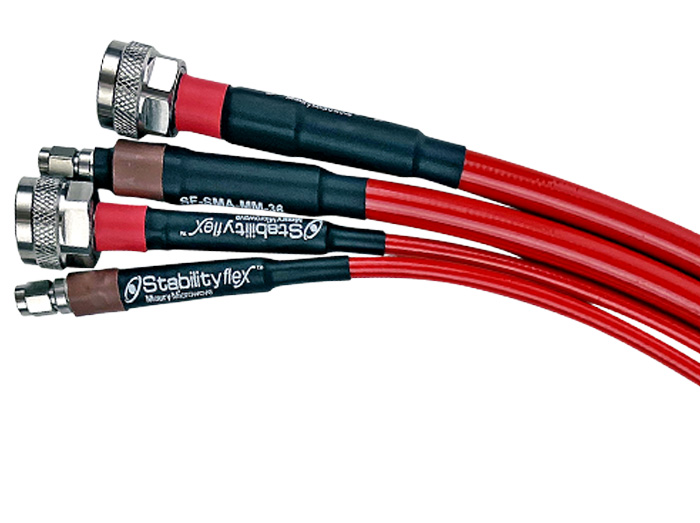

Maury Microwave ColorConnectTM solutions apply the IEEE P287 standard, which uses familiar resistor color codes to indicate connector frequency bands. This intuitive, user-friendly design helps prevent costly mismates, saves valuable time, and increases efficiency.

Maury applies these color bands to a range of interconnects and related tools, including precision-grade adapters, phase-stable cable assemblies, high- performance attenuators, and torque wrenches, all geared for maximum ease of use and repeatable, reliable performance.