Electromagnetic compatibility (EMC) testing ensures that electronic devices operate as intended in dense wireless environments without causing or being significantly affected by interference. EMC standards are pivotal across various industries, spanning automotive, aerospace, military, and medical applications.

This post will provide an overview of different types of EMC testing, focusing on common EMC immunity test setups and the critical components used to ensure high-integrity and highly accurate measurements.

EMC Testing – Emissions & Immunity

All electronic devices emit some level of electromagnetic interference (EMI), but those emissions must stay within defined limits to not disrupt nearby electronics. EMC emissions testing is used to measure, monitor, and analyze the level of EMI a device generates, ensuring compliance with required standards.

EMC immunity testing, on the other hand, evaluates a device’s resilience to electromagnetic energy from external sources. This testing is critical for real-world operation, as devices are expected to perform while in environments filled with various electromagnetic disturbances.

EMC Immunity Testing – OTA & Stripline

EMC immunity testing can be performed using different approaches, such as over-the-air (OTA) radiated immunity testing and conducted immunity testing using a stripline fixture.

Radiated immunity testing

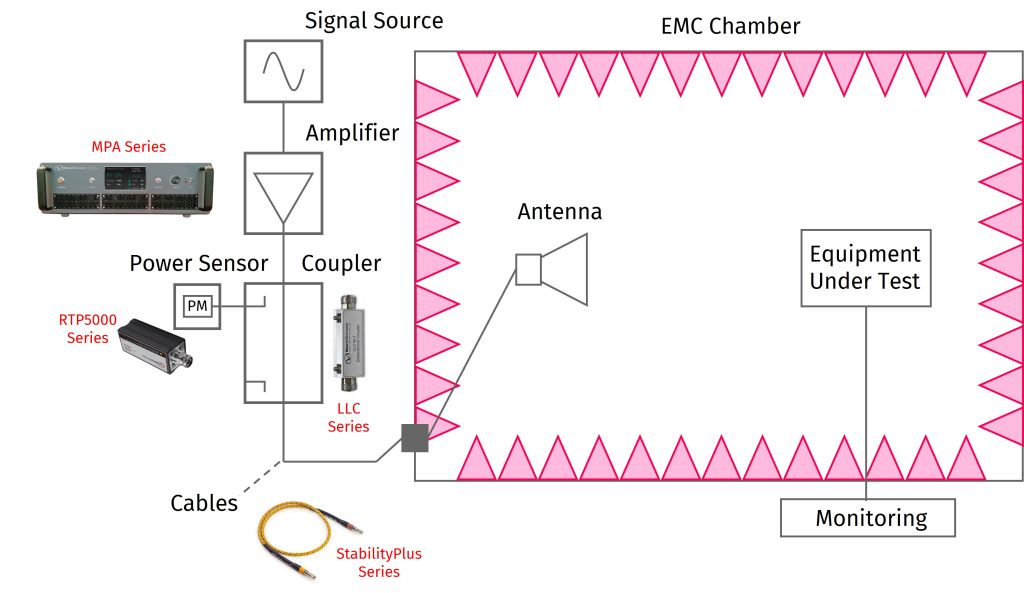

In radiated setups, the DUT is situated inside a large chamber where it will be subjected to different interference levels. The chamber creates a controlled test environment to ensure results are free of any external influences or reflections.

A simplified immunity test setup involves several key components, from amplifiers to peak power sensors.

- A signal generator is used to create the EMC test signal.

- Critical to the test setup, a broadband amplifier boosts the signal to a power level high enough to generate the required field strength inside the chamber. The amplifier must maintain high linearity over a wide frequency range for optimal, high-integrity testing.

- A directional coupler samples a portion of the power without disrupting the signal path, enabling low-loss signal monitoring.

- Peak power sensors measure the sampled power, accuracy tracking and analyzing signal profiles and power levels.

- Amplitude and phase stable cables deliver the amplified signal to the antenna with minimal distortions and loss.

- The antenna inside the chamber converts the amplified signal into radiated energy inside the chamber, exposing the DUT to the required field strength for testing.

- Inside the chamber, the DUT is the equipment being tested for immunity to radiated electromagnetic fields.

Stripline testing

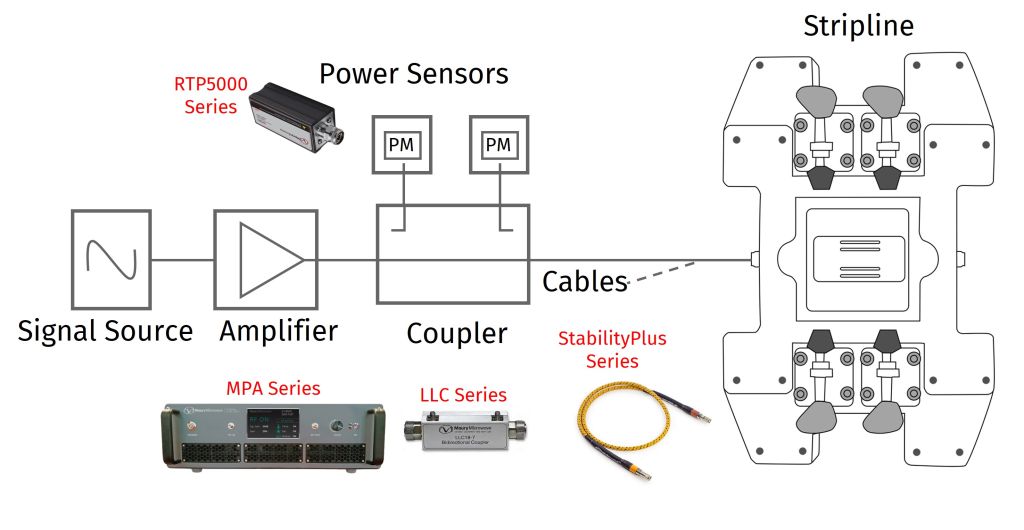

While OTA testing in EMC chambers is ideal for larger systems, stripline testing offers a compact, precise method for evaluating smaller devices and subsystems.

The test setup includes many of the same components as OTA immunity testing – a signal generator, wideband linear amplifier, a high-power low-loss coupler, real-time peak power sensors, and amplitude/phase stable cables. A key difference is the stripline fixture, which exposes electromagnetic fields to smaller DUTs.

Advanced Solutions for EMC Testing

Whether radiating electromagnetic energy inside an EMC chamber or conducted through a stripline, each requires a high-performance amplifier to ensure the power levels needed for accurate results are reached.

The Maury Microwave MPA-series broadband amplifiers provide the output power, linearity, wide frequency range, and high performance needed to meet EMC test requirements.

Key features include:

- Solid-state GaN PAs

- Broadband design

- Testing above 6 GHz: 6 GHz to 40 GHz

- Sub-6 GHz testing: 0.5 GHz to 6 GHz

- Output Power:

- Testing above 6 GHz: 6 GHz to 18 GHz, 250 W; 18 GHz to 40 GHz, 40 W

- Sub-6 GHz testing: up to 500 W (custom options available in the kW range)

- Remote control

- Integrated coupler

- Integrated protection circuitry

Maury solutions for EMC extend beyond amplifiers, with the RTP5000 series high video bandwidth, real-time power sensors to measure, monitor, and verify power levels; LLC series high-power, low-loss couplers providing high-directivity and low insertion loss; and StabilityPlus cables ensuring accurate and reliable signal transmission with excellent amplitude and phase stability.

With Maury, engineers can trust in the reliability and repeatability of their EMC measurements.