RF and microwave connectors are essential in test setups, but simple oversights, such as using incompatible connector interfaces or careless storage, can degrade performance and cause costly equipment damage. In this blog, we’ll cover a few practical tips to keep your connections strong and stable, as well as review how phase stability ensures reliable and accurate results.

Incorporating Connector Care Best Practices

To keep your connectors performing at their best, follow these simple steps and incorporate them into your everyday routine.

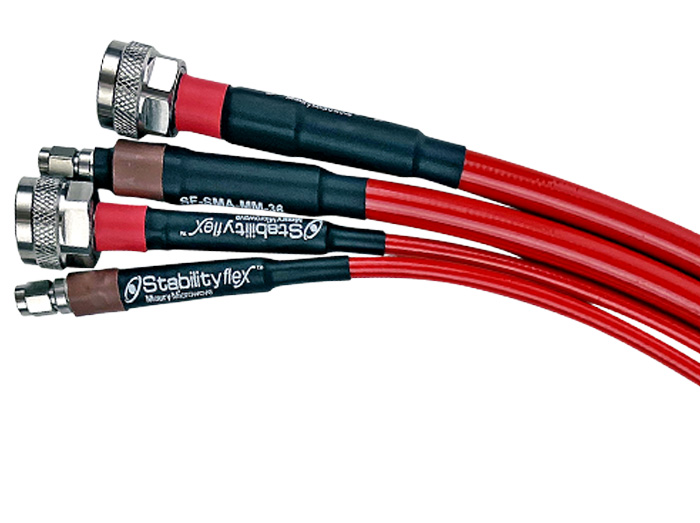

Simplify your setup with color-coded connectors

Accidentally mating incompatible types, such as a 2.92mm with a 2.4mm, in a fast-paced lab can delay projects to repair damaged equipment. Color-coded connectors (following the IEEE P287 high-frequency connector/adapter color scheme) help engineers quickly identify what they need, from matching connector sizes and mating compatible types to choosing an adapter for incompatible connections.

Before using connectors, give them a look first

Once you’ve found the right connector, check for obvious signs of damage and poor concentricity. Misalignment of the center pin/socket can impact signal transmission and cause excessive wear or damage.

Don’t let contaminants affect performance

Dust and debris prevent proper contact and alter impedance. Cleaning before use, whether using a lint-free swab with alcohol or a burst of low-pressure air, helps maintain signal integrity and avoid reflections or distortion.

Check pin depth before you connect

A pin that protrudes too far out can break socket material, while one that’s recessed may fail to make proper contact. Using a mechanical gage to measure pin depth before mating ensures the connector is within specifications.

Do you want a refresher on how to use a gage and torque wrench properly? Watch this insightful, how-to video.

Store your connectors with care

Uncapped connectors left scattered in a drawer can lead to haphazard contact between components, bent pins, scraped threads, and introduce contaminants. Using cases with foam inserts, proper labeling, and protective caps keep connectors ready for your next test setup.

Maintaining Cable Phase Stability

Proper connector care, such as inspecting before use and ensuring concentricity, is a crucial factor in maintaining the phase stability of a cable assembly. Phase shifts are expected – where the signal experiences a certain delay, exiting the cable later in time compared to an ideal, fixed reference – and are typically measured and compensated for during testing.

Unpredictable shifts, however, caused by sudden damage, wear overtime, cable flexure within test environments, and temperature changes, can severely impact measurement accuracy and precision applications.

Measuring cable phase stability involves different techniques, including flexure testing and quantifying measurement uncertainty.

- Flexure testing: Cables are measured in a straight position and then bent or coiled in controlled ways while a VNA monitors phase changes. This test captures performance in both static conditions and when moved or reconnected frequently across the cable’s frequency range.

- Uncertainty analysis: By continuously measuring S-parameters during typical cable movement, engineers can quantify the uncertainty that cable flexure and handling adds to a DUT measurement.

Ensuring Strong, Stable Connections

Taking some time to care for your connectors through using color-coded components, regular inspections, cleaning debris, measuring pin depth, and organized storage, not only contributes to maintaining phase stability, but ensures high-integrity results and the utmost confidence in every connection.