High power microwave (HPM) technology is an effective tool to counter hostile electronic systems quickly and precisely. In this post, we’ll explore what HPM systems are, how they work, and how to characterize performance to ensure decisive results in mission-critical engagements.

How HPM System Work

HPM systems are a type of directed energy weapon (DEW) that emit powerful beams of electromagnetic energy at identified targets. Electronic threats, from drone swarms to communications links, in the beam footprint are neutralized electromagnetically, making them efficient, non-kinetic engagement options. Compared to weapons relying on physical impact to damage a target, HPM offer lower collateral damage, speed-of-light delivery, and repeated engagements, within platform and thermal limits.

HPM weapons first generate a controlled waveform, which defines signal characteristics such as the frequency, phase, pulse timing, and modulation. Next, the signal is amplified to power levels high enough to drive the antenna, which defines the beam’s width, direction, and radiates electromagnetic fields at required intensities for maximum effect on the target.

Traveling at the speed of light, any electronic device within this field often experiences sudden system failure from factors such as damaged components, EMI-induced timing errors, or overloaded sensors and receivers.

HPM Platform Versatility

HPM systems are highly adaptable, capable of launching from a variety of different platforms. Compact, mobile HPM systems are often mounted atop vehicles, used to quickly engage small, unpredictable aerial or ground threats, such as UAVs or remote sensors.

Fixed, land-based HPM systems are used to protect critical infrastructure and installations against hostile forces. Naval ships as well as airborne platforms can also integrate HPM to provide a layered defense and rapidly disrupt approaching threats.

Characterizing HPM performance for Mission Readiness

Each stage of the HPM signal chain must be properly evaluated in realistic operating conditions to ensure stable energy delivery and optimal performance. Selecting solutions across signal generation, amplification, power analysis, device characterization, and interconnects ensure HPM technologies are tested and validated effectively and reliably.

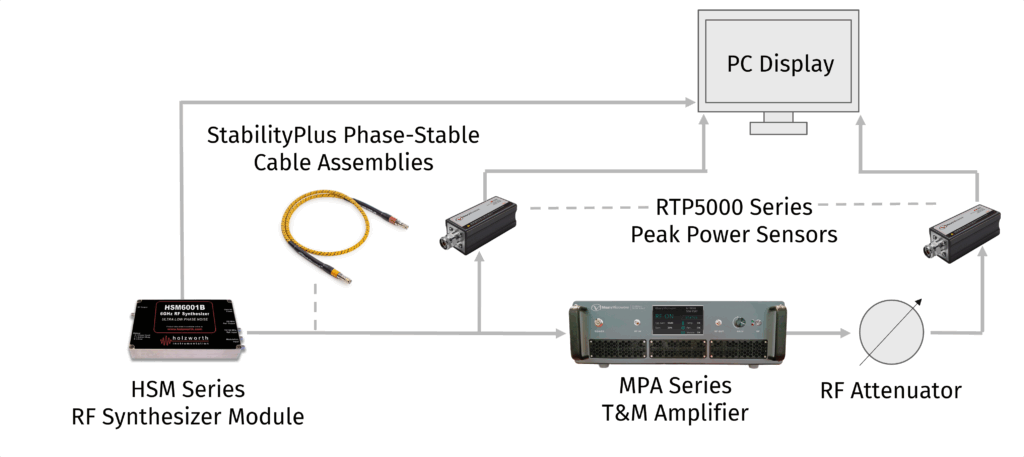

The test setup below features a comprehensive range of solutions demonstrating critical capabilities needed to stress and analyze HPM performance

Key test components for HPM analysis include the following:

- Signal generators: Choosing a synthesizer that provides clean, phase-stable pulses is able to emulate operational waveforms.

- Amplifiers: A high-power, linear, broadband amplifier raises signal levels without introducing distortions.

- Interconnects: Phase-stable, durable cables maintain amplitude and timing consistency between instruments and preserves measurement accuracy.

- Power sensors: Real-time peak power sensors with fast rise times capture pulse shape characteristics and rapidly rising pulse edges. In the above test setup, directional couplers at the amplifier input and output route forward and reflected signals to two sensors on each side. With this, engineers can measure return loss into the amplifier, amplifier efficiency, return loss at the antenna, and effective radiated power (ERP), providing a complete view of HPM system performance from source to radiated output.

- Device characterization tools (load pull): Engineers adjust load conditions to determine maximum deliverable power and optimize amplifier stages for HPM operation.

Together these instruments allow engineers to stress, test, and validate every link in the HPM signal path, ensuring each pulse is focused and mission ready.